Our company specializes in manufacturing various mask machine blades. These blades are professionally used for cutting and pressing molds of various mask cloths. With complete varieties, customizable non-standard specifications, short delivery time and reasonable prices, we are the best partner for mask machine manufacturers and mask machine production users.

Our main products are:

Disposable civilian mask blades, disposable ordinary medical mask blades, anti-virus medical mask blades, ear strap cutting blades, mask machine scrapers, mask machine nose bridge cutters, N95 mask scissors, N95 mask knurling molds, N95 mask roll cutter related accessories knives mold.

product name :

Disposable civilian mask blades, disposable ordinary medical mask bladesbrand :

San quShipping Port :

Shanghai/Guangzhou or otherColor :

Natural colorLead Time :

10-15 days after receiving the depositPayment :

T/T,Western unionMaterial :

skd11,cr12mov,h13,9crsi,skd-61,etc.MOQ :

1pcs

| Material: | Tungsten steel alloy,HSS,LD,SKD11,Cr12,Cr12mov,T8,T10,M42,65M,420J.etc. |

| hardness: | HRC46-93 |

| Quench: | Full body heat treatment |

| Surface roughness: | Ra0.2 |

| Thickness tolerance: | ±0.00008" |

| Outer diameter tolerance: | ±0.001″ |

| Parallelism: | ±0.0001″ |

| Standard sizes: | Customized according to drawings |

Our advantage:

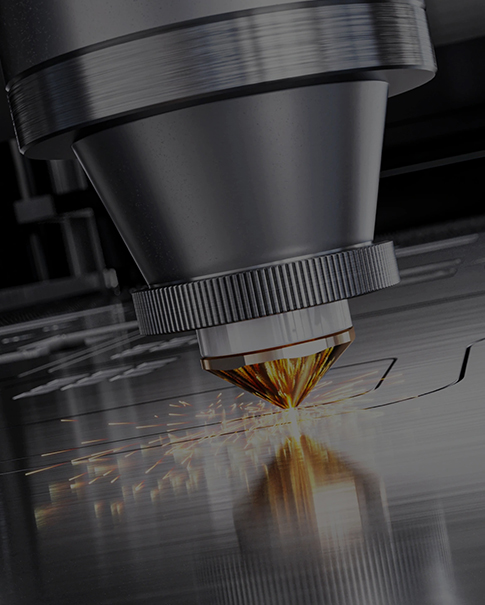

The mask machine blade is one of the important components used in mask machinery. Mask machine blades are mainly used for cutting, pressing and forming mask materials to ensure the precise size and high-quality production of masks. These blades are usually made of high-quality alloy steel materials, which are wear-resistant, corrosion-resistant, high hardness and superior cutting performance.

The design and manufacturing of mask machine blades are very critical because they directly affect the quality and output of masks. Excellent mask machine blades can ensure that the cutting edge of the mask is smooth and burr-free, and can withstand long-term high-intensity work. In addition, some mask machine blades also feature quick replacement and adjustment to adapt to the production needs of different mask types and sizes.

Our company focuses on the design and manufacturing of mask machine blades and has advanced production equipment and technical teams. We use high-quality alloy materials, precision machining and heat treatment processes to ensure high quality and long life of the blades. Our mask machine blades pass strict quality control and enjoy a good reputation in the market.

Whether it is the production of medical masks or ordinary masks, our mask machine blades can provide stable and reliable performance to meet customer needs. We are committed to providing customers with high-quality products and comprehensive technical support to ensure their success in the fierce market competition.

If you have needs for mask machine blades or other related products, please feel free to contact us. We will wholeheartedly provide you with the best solutions and services to help you achieve greater success.

.

Our production process :

1.Cutting 2.Forging 3.Plastic surgery 4.Heat treatment 5.Modification 6.Slice

7.Slice 8.Sharpen 9.Plastic surgery 10.fine grinding 11.Plastic surgery

12.Chamfer 13.Test 14.Package 15.Factory

Our products serve all walks of life:Metallurgical industry, plastic industry, food industry, printing industry, electrical appliance industry, rubber industry, woodworking industry, shipbuilding industry, light industry machinery industry, etc.

Packing&Shipping

Efficient logistics and distribution: We use fast and reliable logistics partners to ensure that your order can be delivered in time. We work with world-renowned logistics companies to provide flexible logistics options and full tracking services so that you can always know the shipping status of your goods.

FAQ:

1:Are you Trading company or Factory?

We are factory,and we have experience for 20 years.

2:Can I have one piece for sample?

Of course yes, nothing can prove our production's quality but sample. You can order one piece on line and our customer service will contact with you as soon as possible.

3: How long is your delivery time?

Generally, it will be within 24 hours after received the payment,Mass production need 20days,Make mould need 15days.

4: What’s kind of trading term can you do?

If you have your usually trading term, please tell our customer service, if not , we can do Ex-works, FOB,CFR,CIF etc .

5: How about the quality of blades ?

Our blades adopt advanced technology. Moreover, we carry out strict supervision during productionand make sure every finishedproduct with high quality.

Tags :