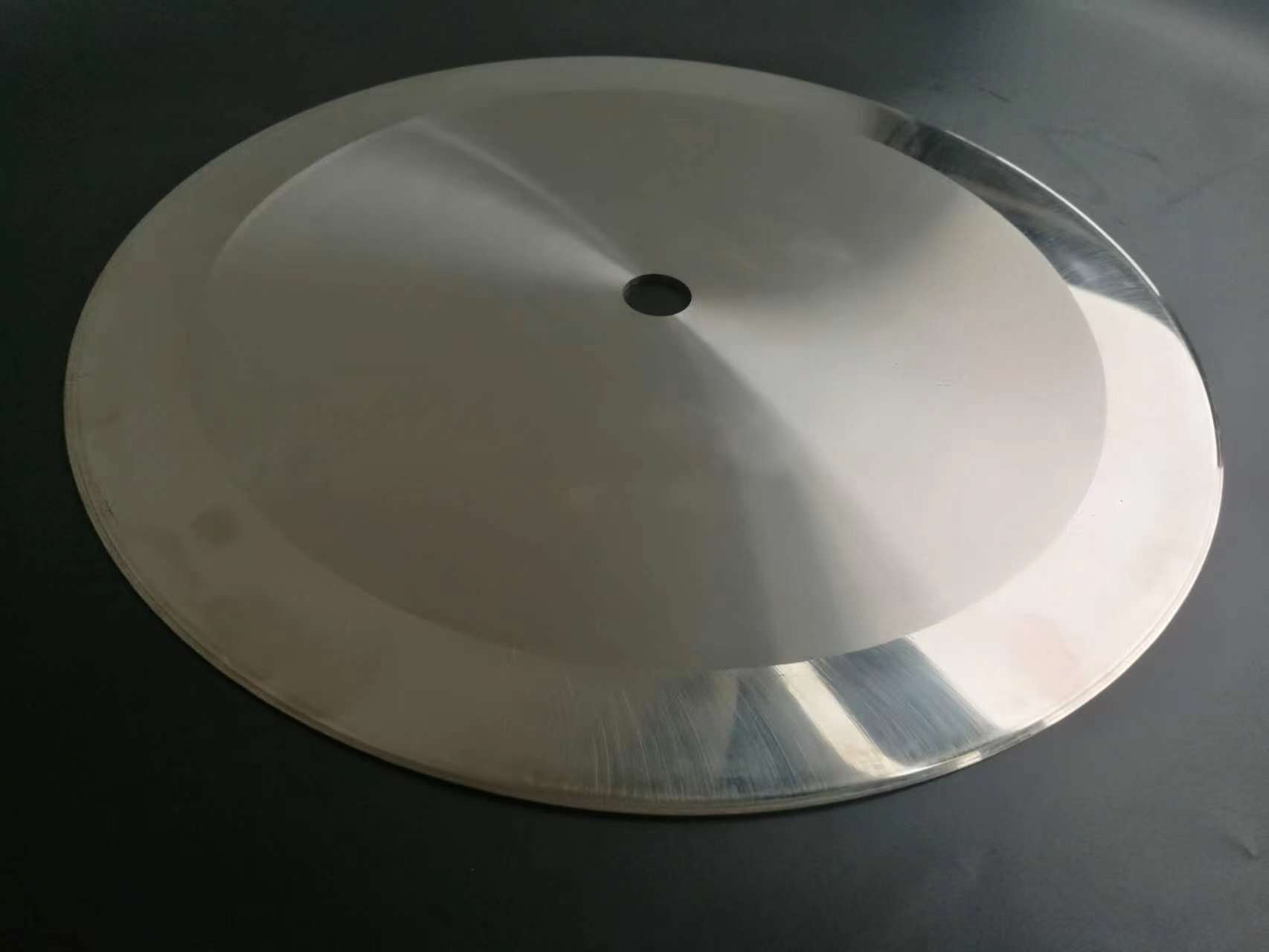

A round blade is a circular cutting tool. It is usually used to cut soft materials such as paper, plastic, leather and cloth. The cutting edge of a round blade is flat and usually requires pressure to make it cut through material effectively. Round blades are usually made of metal, but there are some versions made of plastic or wood.

product name :

Factory cutting machine accessories round cutting knife leather paper round cutting bladebrand :

San quShipping Port :

Shanghai/Guangzhou or otherColor :

Natural color/silver/black/golden yellow or otherLead Time :

15-20 days after receiving the depositPayment :

T/T,Western unionMaterial :

65MN、9CRSI、SKD-11、SKH-91、SKH-51、CR12Mov、etc.MOQ :

1pcs

| Size | We can customize according to your requirements |

| Material | 65MN、9CRSI、SKD-11、SKH-91、SKH-51、CR12Mov、etc. |

| Hardness | HRC46-93 |

| MOQ | 1PCS |

| Thickness tolerance: | ±0.00008" |

| Surface roughness: | Ra0.2 |

| Outer diameter tolerance: | ±0.001″ |

| Parallelism: | ±0.0001″ |

| Package: |

1.Apply anti-rust oil 2.Packed in plywood wooden box 3.Increase moisture-proof and anti-smashing measures |

| General size | |||

| Outer diameter*inner diameter*thickness | Outer diameter*inner diameter*thickness | Outer diameter*inner diameter*thickness | Outer diameter*inner diameter*thickness |

| 28×5×0.3 | 45×22×1 | 45×8×0.3 | 45×10×0.5 |

| 50×12×0.5 | 50×16×1 | 60×10×0.3 | 60×10×0.5 |

| 60×15×0.6 | 70×16×0.8 | 76×18×2 | 76.2×25.4×1.2 |

| 76×25.4×1.2 | 76×26×2 | 80×18×0.5 | 80×22×1.2 |

| 80×25.4×1.2 | 80×25.4×2 | 80×40×1 | 90×20×0.8 |

| 90×25.4×1.2 | 90×55×2 | 100×15×0.8 | 100×16×1 |

| 100×20×0.5 | 100×20×1 | 100×25.4×1.5 | 100×25.4×2 |

| 100×27×1 | 100×27×2 | 100×32×1.5 | 100×50×2 |

| 100×50×4 | 105×30×2 | 110×25×0.7 | 110×25.4×2 |

| 110*25.4×1.5 | 110×32×2 | 110×40×2 | 110×50×2 |

| 110×55×2 | 110×70×1.5 | 120×20×0.8 | 120×25.4×2 |

| 120×32×2 | 120×40×2 | 120×55×2 | 125×25.4×2 |

| 125×50×1 | 125×54×2 | 125×55×2 | 130×25.4×2 |

| 130×30×0.9 | 140×25×1 | 140×25.4×2 | 140×25.4×5.5 |

| 150×25.4×2 | 150×25.4×1.5 | 150×32×0.8 | 150×55×2 |

| 150×80×3 | 150×80×4 | 160×25.4×2 | 180×25.4×2 |

| 200×25.4×2 | 200×25.4×2.5 | 200×55×2 | 200×25.4×3 |

| 250×25.4×1.8 | 250×25.4×2 | 250×25.4×2.5 | 250×25.4×3 |

| 280×25×1.8 | 300×25.4×2.5 | 300×25.4×3 | 300×32×3 |

| 300×38.1×3 | 350×25.4×3 | 350×32×3 | 350×38.1×3 |

| 350×40×3 | 350×58×3 | 380×40×3 | 380×25.4×3 |

| 400×25.4×3 | 400×58×3 | 400×60×3 | 450×25.4×3 |

| 500×25.4×3 | 550×25.4×5 | 610×25.4×4.7 | |

Product display:

Our diameter, thickness and material are customized according to customer needs.

The general materials of the slitting and separation discs we produce are GCr15, 9CrSi, SKD-11, etc. We undergo heat treatment, leveling, fine grinding, polishing and chrome plating during production to improve its surface wear resistance and smoothness. Make the separated steel bars neat and smooth

Our advantage:

Round knives are widely used for cutting paper, plastic film, fabric, foam, rubber, copper foil, aluminum foil, graphite, etc. This type of knife is sharpened by professional equipment. It has beautiful appearance, high precision, long life and high cost performance.

Mainly used in dividing knife production line. The company has professional production experience and uses high-quality imported steel. Manufactured by vacuum heat treatment. With extremely high wear resistance and size, the knife edge has been rigorously tested. Using German vacuum erasing technology, the heat treatment is uniform, the plate hardness is HRC58-65, and CNC processing equipment is used to ensure accuracy, and the plate accuracy reaches 0.01-0.02mm. The flat surface is ground by an ultra-precision grinder and rigorously tested to ensure that the blade tolerance is within 0.03mm. Used for various kraft paper, corrugated paper, rice paper, constant temperature paper, color inkjet paper, decorative base paper, printing base paper, copper foil, aluminum foil, electrodes, etc. It has the advantages of neat, clean and smooth cuts, no burrs, less blade replacement, long service life, and high cost performance.

The blade is made of high-quality imported steel. Generally used: 65MN, 9CRSI, SKD-11, SKH-91, SKH-51, CR12Mov, W6MO5CR4V2, SKH-51, W18CR4V, etc. High, it is an ideal blade to reduce cutting costs and cut high scores.

Our production process :

1.Cutting 2.Forging 3.Plastic surgery 4.Heat treatment 5.Modification 6.Slice

7.Slice 8.Sharpen 9.Plastic surgery 10.fine grinding 11.Plastic surgery

12.Chamfer 13.Test 14.Package 15.Factory

Our products serve all walks of life:Metallurgical industry, plastic industry, food industry, printing industry, electrical appliance industry, rubber industry, woodworking industry, shipbuilding industry, light industry machinery industry, etc.

Packing&Shipping

Efficient logistics and distribution: We use fast and reliable logistics partners to ensure that your order can be delivered in time. We work with world-renowned logistics companies to provide flexible logistics options and full tracking services so that you can always know the shipping status of your goods.

FAQ:

1:Are you Trading company or Factory?

We are factory,and we have experience for 20 years.

2:Can I have one piece for sample?

Of course yes, nothing can prove our production's quality but sample. You can order one piece on line and our customer service will contact with you as soon as possible.

3: How long is your delivery time?

Generally, it will be within 24 hours after received the payment,Mass production need 20days,Make mould need 15days.

4: What’s kind of trading term can you do?

If you have your usually trading term, please tell our customer service, if not , we can do Ex-works, FOB,CFR,CIF etc .

5: How about the quality of blades ?

Our blades adopt advanced technology. Moreover, we carry out strict supervision during productionand make sure every finishedproduct with high quality.

Tags :