As our company's gold medal product, the packaging machine tooth knife is widely recognized in the packaging industry. In order to provide customers with the best quality products and services, our company adheres to rigorous manufacturing processes, scientific methods of use and thoughtful maintenance guidelines. In this blog, we will reveal the production, usage tips and effective maintenance methods of the packaging machine tooth knife to help you better understand, use and maintain the tooth knife.

Production process:

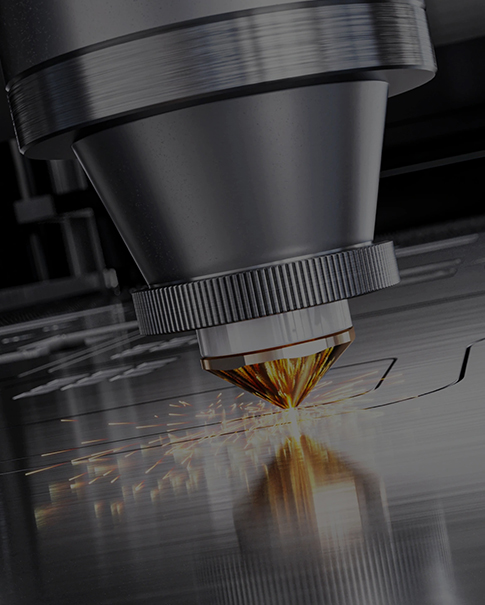

The production of the packaging machine tooth knife undergoes a series of precision processes and strict quality control. First, we select high-quality steel, and after precision cutting and heat treatment, ensure that the knife has excellent hardness and wear resistance. Next, we use advanced CNC machinery and equipment for precision machining to ensure that the geometry and size of the knife are accurate. Finally, after careful polishing and inspection, the packaging machine tooth knife completes the final production process.

Usage tips:

(a) Choose the right tooth knife model: According to different packaging machine models and operation requirements, choose the right tooth knife model and size. Ensure that the tooth knife and the packaging machine are tightly and stably matched to obtain the best cutting effect.

(b) Correct installation and adjustment: Carefully follow the instructions for use, correctly install the toothed knife on the packaging machine, and make necessary adjustments to ensure that the position and angle of the knife are accurate.

(c) Pay attention to personal safety: When using the toothed knife, be sure to wear appropriate protective equipment to avoid accidental injuries.

Maintenance Guide:

(a) Regular cleaning and lubrication: Regularly clean the impurities and chips on the surface of the toothed knife to ensure that the knife is kept clean to improve the cutting effect. At the same time, use appropriate lubricants to lubricate the toothed knife to extend its service life and reduce friction loss.

(b) Avoid excessive wear: Pay attention to the use time and frequency of the packaging machine toothed knife, and replace or repair severely worn knives in time to avoid affecting the cutting quality and safety.

(c) Safe storage: When storing the toothed knife, it should be placed in a dry environment without corrosive gases and dust to prevent the knife from being damaged or corroded.

As a manufacturer, we are committed to providing customers with high-quality packaging machine toothed knives and perfect after-sales service. Whether it is providing customized knives or tracking the use of blades, we are always committed to providing customers with the best product and service experience.

These tips on use and maintenance will help you get the most out of your packaging machine knives and improve production efficiency and product quality. If you have any questions or needs about packaging machine knives, please feel free to contact our professional team and we will be happy to provide you with help and support.

Website: https://www.cnsanqumc.com/

WhatsAPP: +86 17356699004