Blades are widely used in the recycling and plastics industries. Below I will go into detail about how and what kind of blades are used in both industries.

Recycling industry:

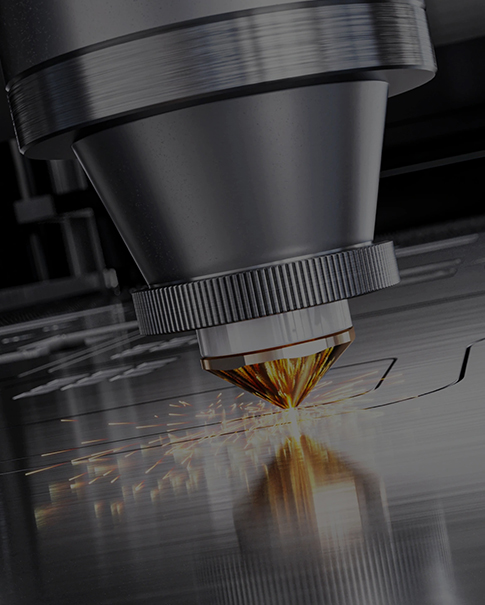

Cutting and dismantling: The recycling industry requires cutting and dismantling of waste items for reuse or recycling. Blades play a key role in this process and are commonly used to cut metal, plastic, cardboard and other materials. The blade needs to have good cutting performance and wear resistance, be able to cut efficiently, and have a certain lifespan.

Fragmentation: The recycling industry also needs to fragment waste items into small particles or powder suitable for subsequent reuse. In shredder processing, commonly used blades include shredder blades and shredder blades. These blades need to have high strength and wear resistance to effectively crush waste items into the required particle size.

Plastic industry:

Injection molds: Plastic products are often produced using injection molds, which include mold blades. These blades are used to inject molten plastic material into the mold during the injection molding process and form the desired part or article. Mold blades need to have high hardness, wear resistance and corrosion resistance to ensure the life and production efficiency of the mold.

Plastic cutting and processing: Plastic products require cutting, trimming, hole processing and other processes during the production process. Blades play an important role in these operations, and commonly used blades include round blades and shaped blades. These blades need to have good cutting performance, rigidity and wear resistance to efficiently cut and process plastics.

The type of blade used depends on the specific application needs and material properties. Usually in the recycling industry, commonly used blade materials include high-speed steel, carbide and engineering plastics; in the plastics industry, commonly used blade materials include high-speed steel, carbide and engineering plastics. Choosing the right blade material can improve cutting efficiency and tool life while ensuring product quality and production efficiency.