Rolling shear slitting machine blade is a tool used for rolling cutting and slitting, which is widely used in various coil processing industries. The following is a detailed introduction to the blades of the rolling shear and slitting machine:

Production Process:

The production process of roller shear slitting machine blades usually includes the following steps:

a. Material selection: According to the specific requirements of the blade, select appropriate tool steel or alloy materials as raw materials.

b. Material cutting: Cut the selected material to specific dimensions.

c. Passivation treatment: Improve the hardness and wear resistance of the blade through processes such as heat treatment.

d. Precision grinding: The blade is finely ground using a precision grinder to achieve the required size and surface quality.

e. Sealing treatment: According to specific requirements, seaming treatment is performed on the edge of the blade to increase the durability and cutting effect of the blade.

f. Accessory installation: Fix the blade on the tool seat on the rolling shear slitting machine to ensure good cooperation between the blade and the machine.

material selection:

Rolling shear slitting machine blades are usually made of materials such as high-speed tool steel, carbide or tool steel to ensure that the blades have high hardness, wear resistance and strength. Specific material selection will depend on the type and requirements of the material being cut.

Main application areas:

Rolling shear slitting machine blades are mainly used in the following fields:

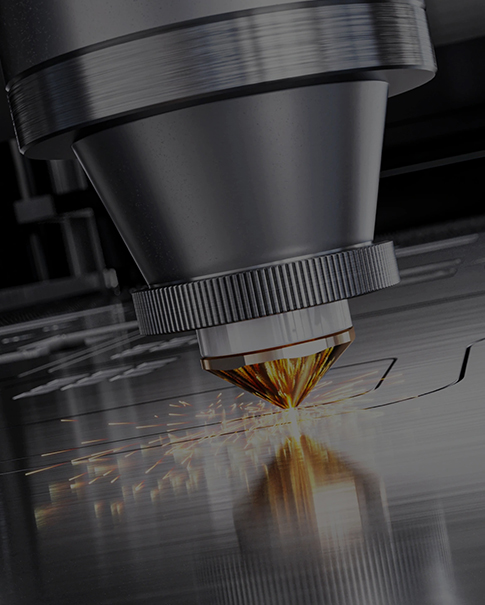

a. Metal coil processing: used for cutting and slitting various metal coils, such as cold-rolled steel, hot-rolled steel, stainless steel, aluminum plates, etc.

b. Plastic coil processing: used for cutting and slitting various plastic coils, such as polyethylene, polypropylene, polyvinyl chloride, etc.

c. Paper roll processing: used for cutting and slitting various paper rolls, such as cardboard, paper, composite materials, etc.

Applicable machines:

Rolling shear slitting machine blades are suitable for various rolling shearing and slitting machines, including automatic rolling shearing and slitting machines and manual rolling shearing and slitting machines. These machines are usually equipped with specialized tool holders and seats to ensure the stability and precision of the blade during the cutting process.

To sum up, the roller shear slitting machine blade is a cutting tool used for coil processing of metals, plastics and paper. Through precise production processes and appropriate material selection, the blades are ensured to be efficient, precise and durable during the cutting process. Widely used in coil processing in various industries.

Our factory-made blades feature premium materials, precision machining, and reliable performance. It is widely used in many fields and can be adapted to various processing equipment. Whether cutting, shearing or crushing, this blade can provide customers with efficient and stable processing solutions. If you need a custom blade or for more details, please feel free to contact us.