Popular Searches :

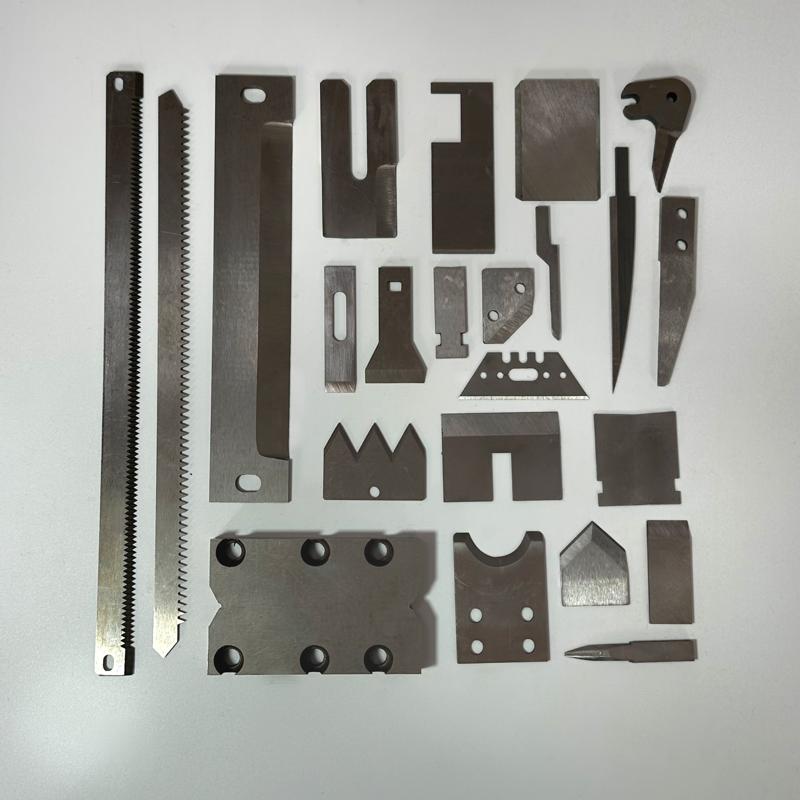

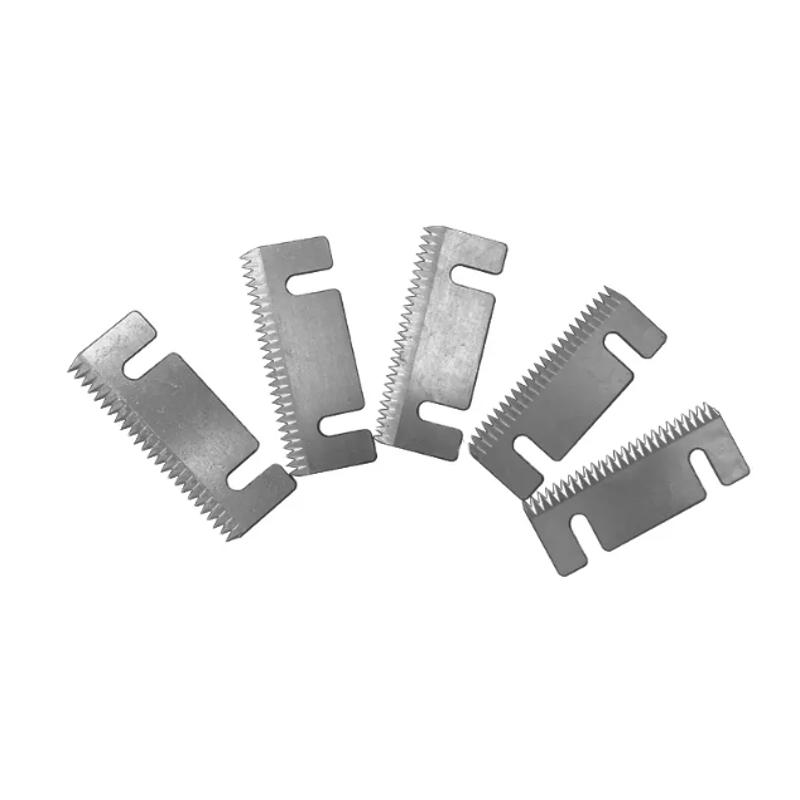

packaging machine knives shearing machine blade plastic crusher blade crusher bladesPopular Searches :

packaging machine knives shearing machine blade plastic crusher blade crusher blades

Tags :

Tags :

location

Whatsapp : +8617356699004

Copyright © 2025 Ma'anshan Sanqu Machinery Technology Co., Ltd. All Rights Reserved.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)