Dear customers and friends, welcome to the official blog of Sanqu Mechanical Tool Technology Co., Ltd. As an industry leader specializing in the production of various blades, our proud ultrasonic blades will be the focus of this article. Let's explore how ultrasonic blades can bring revolutionary breakthroughs to the cutting process with their excellent precision and high-quality materials.

The market competition is increasing day by day, and the manufacturing industry has higher and higher requirements for cutting quality and precision. This requires blade manufacturers to provide more high-precision cutting tools to meet customer needs. Ultrasonic blades are becoming the first choice for many industries with their unique working principle and outstanding performance.

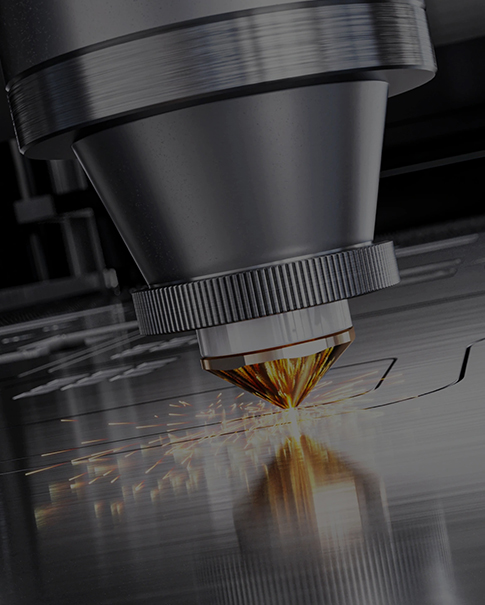

What is the principle of ultrasonic blades? Ultrasonic blades use high-frequency sound waves generated by electromagnetic vibration to transfer energy to the blade edge to achieve material cutting. Compared with traditional blades, ultrasonic blades have outstanding advantages such as high vibration frequency, low cutting force, and small heat-affected area. It is these characteristics that enable ultrasonic blades to achieve higher precision and more detailed cutting effects during the cutting process.

The Sanqu team pursues excellent quality as the goal, and through continuous optimization of blade design and strict control of the manufacturing process, the precision of ultrasonic blades has been raised to a new level. The parallelism and straightness of our ultrasonic blades, which we are proud of, can reach an amazing 0.002mm. This precision far exceeds the level of traditional blades, providing customers with a more precise cutting experience and effectively improving production efficiency.

In addition to excellent precision, the materials we use are also an important part of the advantages of ultrasonic blades. We select high-quality materials to ensure the hardness, wear resistance and corrosion resistance of the blades, thereby extending the service life of the blades. This means that customers can get longer cutting effects with one investment and reduce the cost of maintenance and replacement of blades.

Whether in the field of medical device manufacturing, electronic component processing or fine craftsmanship, ultrasonic blades have shown their great potential. It can not only achieve high-precision cutting, but also adapt to the processing of various complex-shaped materials, such as cellulose materials, plastics, fiberglass, etc. This makes ultrasonic blades an indispensable choice for cutting processes in many industries.

As Sanqu Mechanical Tool Technology Co., Ltd., we are committed to continuous innovation and improvement to meet customers' continuous pursuit of cutting accuracy and process requirements. Our ultrasonic blades are becoming a highly recognized cutting tool in the market with their ultra-high precision and high-quality materials. Choosing our ultrasonic blades will give you a more precise and efficient cutting experience, thereby improving your production efficiency and moving towards success.

If you have any needs for our products or want to know more information, please feel free to contact us. The Sanqu team looks forward to working with you to create a better future!

Contact number: +86 17356699004

WhatsAPP: +86 17356699004

Website address: https://www.cnsanqumc.com/

Email address: sanqu@cnsanqumc.com