Round blades are a common cutting tool that can be used in many industries and fields. The following are some examples of bisphenol A epoxy resin applied to circular blades:

1. Woodworking industry: Bisphenol A epoxy resin can be used to make woodworking round blades for cutting wood, planing and processing wood products. This epoxy offers high strength and abrasion resistance, providing longer cutting life and better work results.

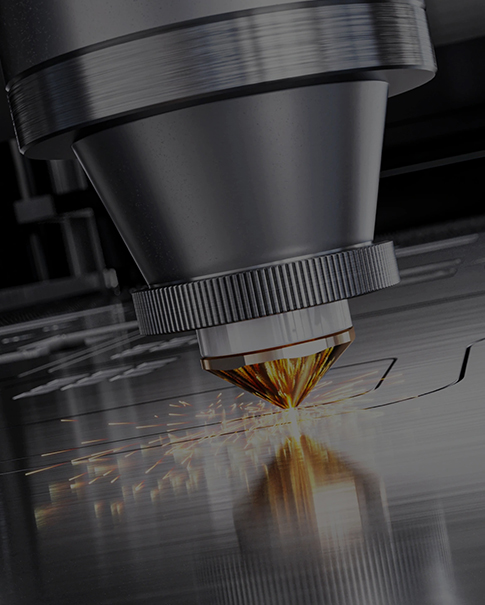

2. Metal processing industry: In the metal cutting and processing process, bisphenol A-type epoxy resin is used to manufacture high-speed steel round blades. This epoxy provides higher hardness and wear resistance, making the blade more durable and effective when cutting metal.

3. Printing industry: Bisphenol A-type epoxy resin is also widely used in the manufacture of printing blades. These blades are commonly used for cutting paper, cardboard, and other printed materials. Epoxy provides the rigidity and durability the blade needs for crisp, precise cuts.

4. Plastic processing industry: In the plastic cutting and processing process, bisphenol A epoxy resin can be used to make circular cutting blades for cutting plastic sheets, films and other plastic products. These blades are highly rigid and wear-resistant for efficient cutting and machining.

It should be noted that bisphenol A-type epoxy resin needs to follow specific process and formula requirements when preparing blades to ensure the stability of blade quality and performance. In actual applications, the specific blade design and manufacturing process also need to consider other factors, such as the type and thickness of the material being cut. Therefore, when designing and selecting round inserts, it is recommended to consult a professional tool manufacturer or engineer for more accurate advice and guidance.